CARBONLOOP

INNOVATION

Our accelerated decarbonisation service is made possible

through a process combining the production

of renewable energies and carbon sinks.

All of it with a short supply chain, starting with biomass waste.

Our accelerated decarbonisation service is made possible

through a process combining the production

of renewable energies and carbon sinks.

All of it with a short supply chain, starting with biomass waste.

A turnkey solution to decarbonise industry in an effective, long-term and local way

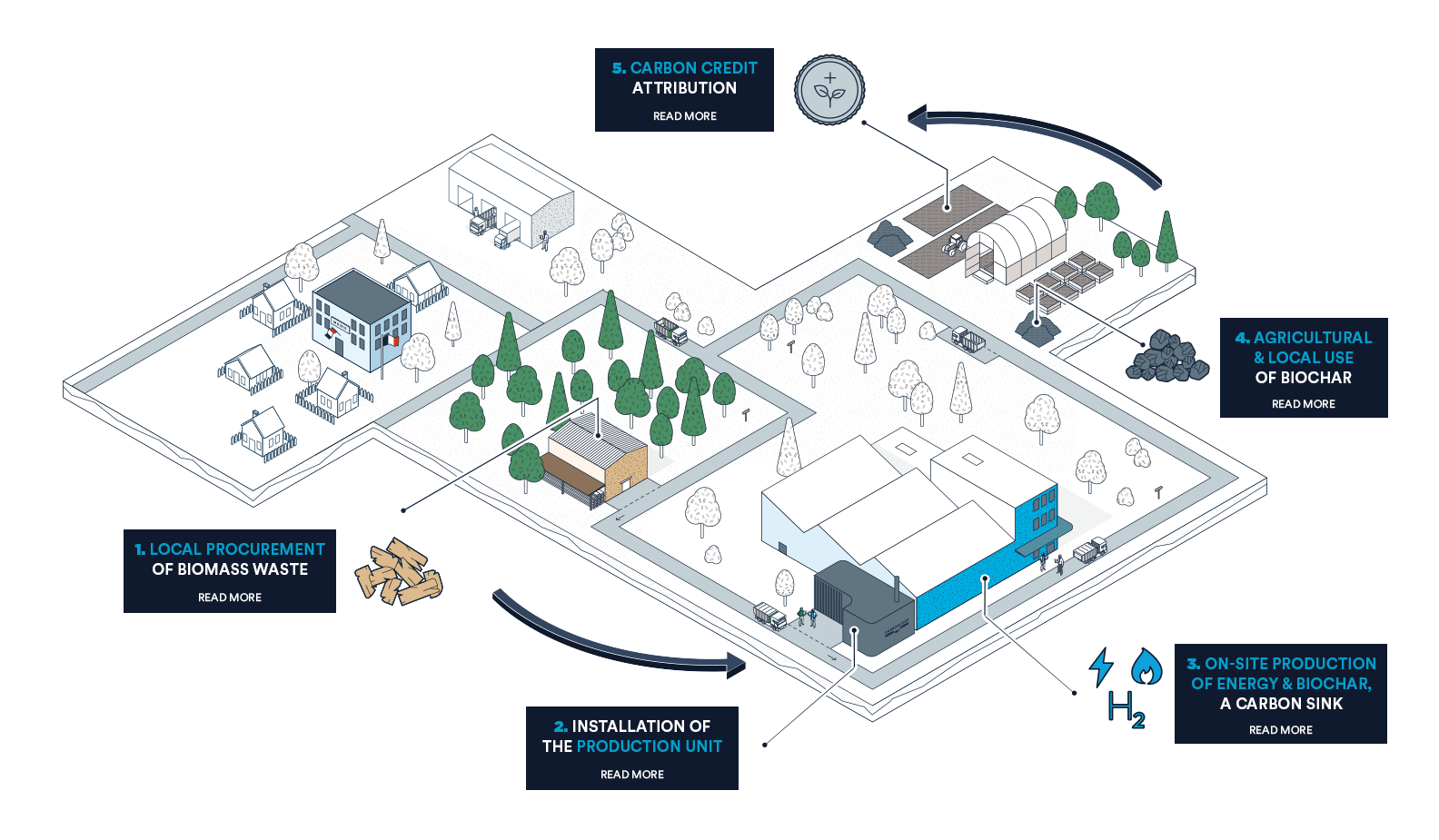

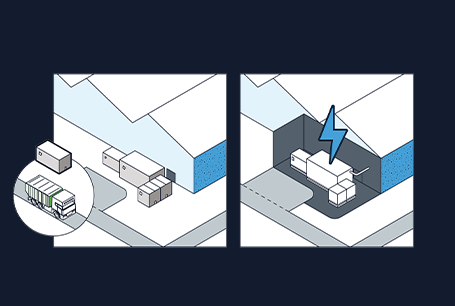

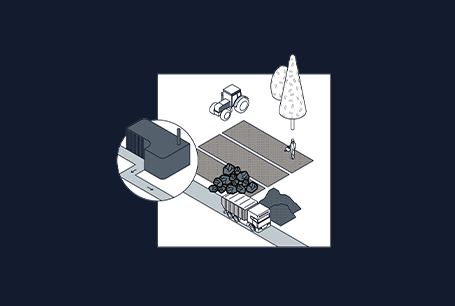

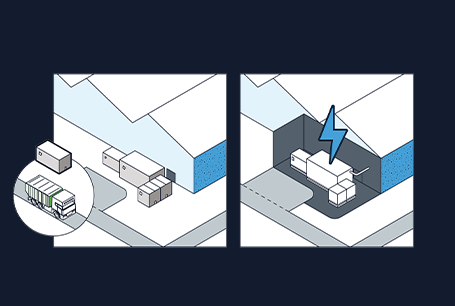

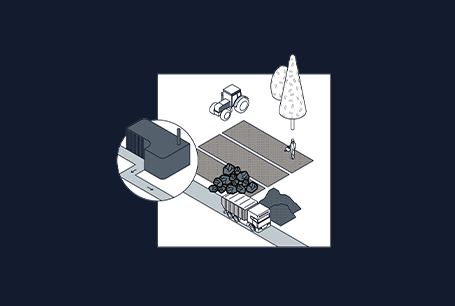

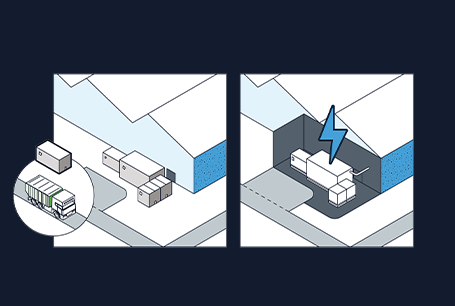

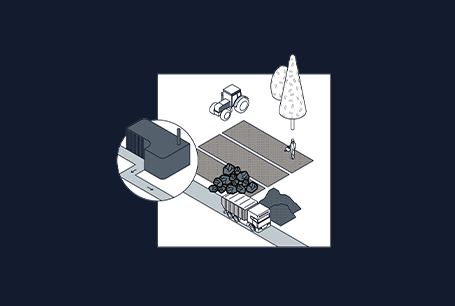

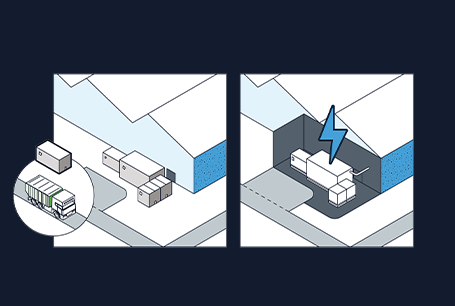

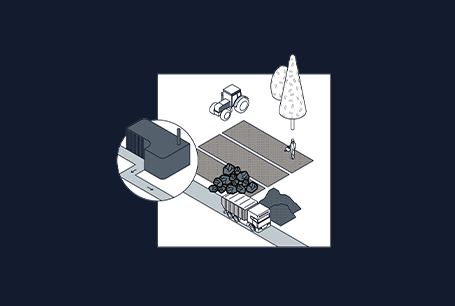

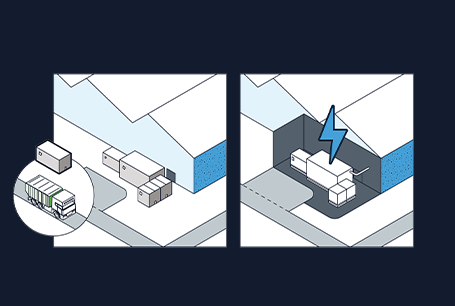

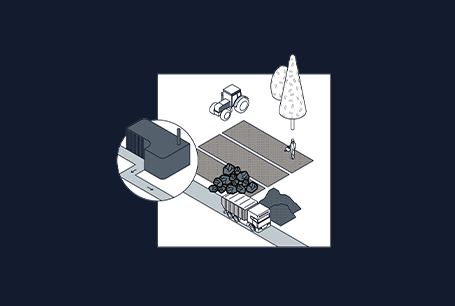

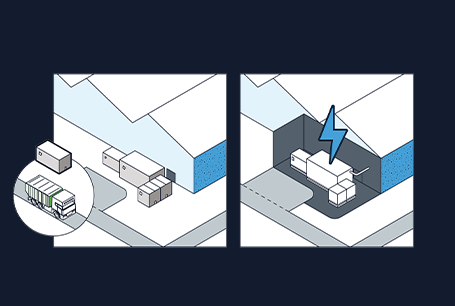

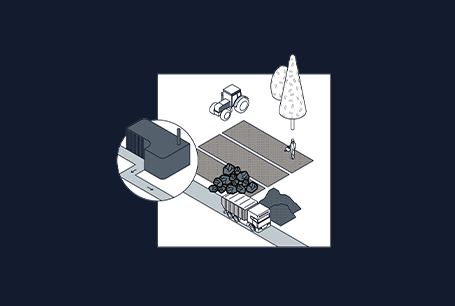

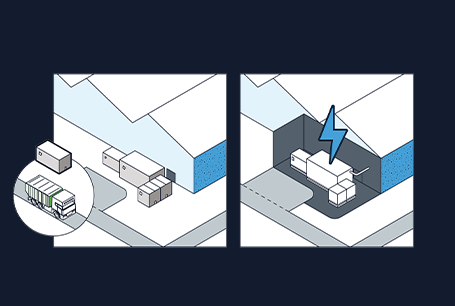

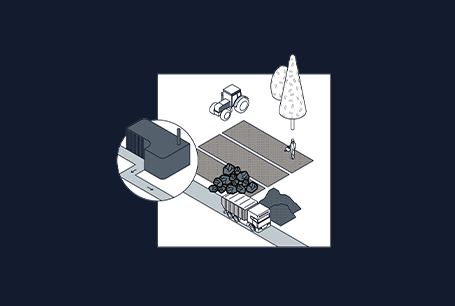

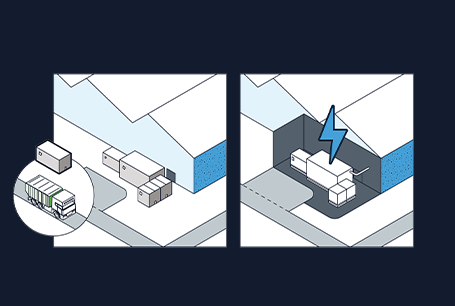

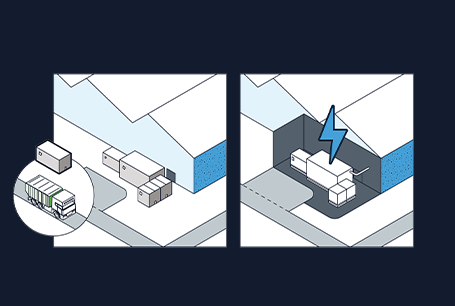

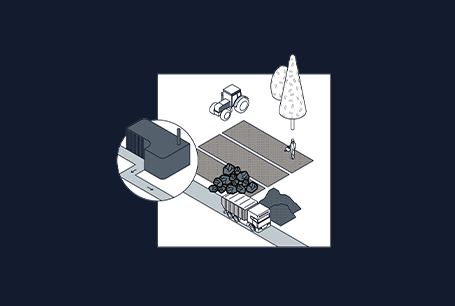

The Carbonloop production unit is supplied locally with biomass residues that would not

otherwise be used (natural or industrial residues from forest maintenance, agriculture

or the wood industry, such as bark, wood chips or straw).

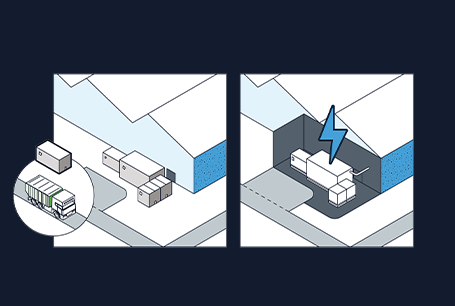

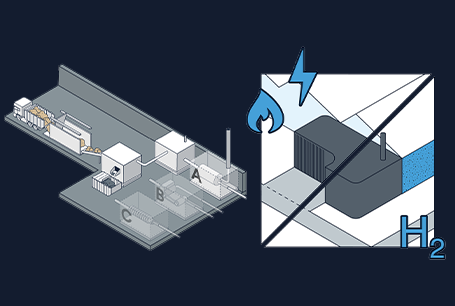

The production unit consists of 3 modules, each the size of a 40-foot container,

which arrive already assembled. It is easy to install on an industrial site.

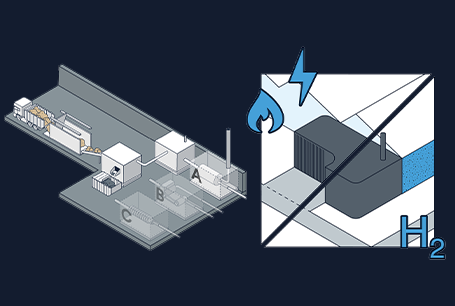

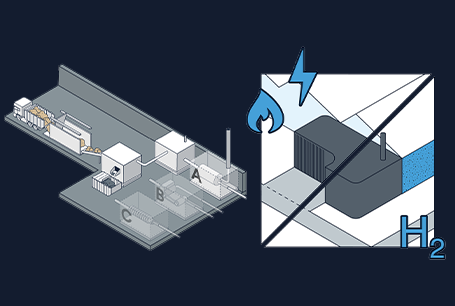

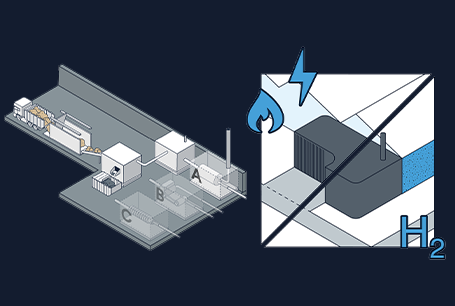

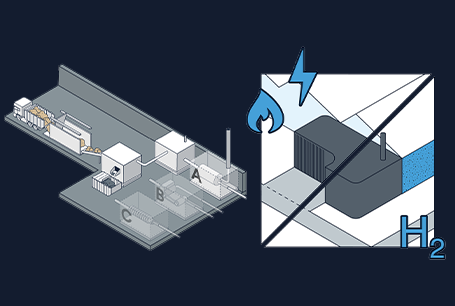

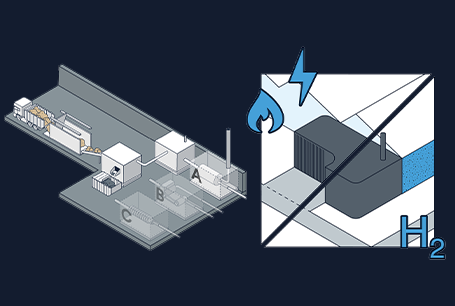

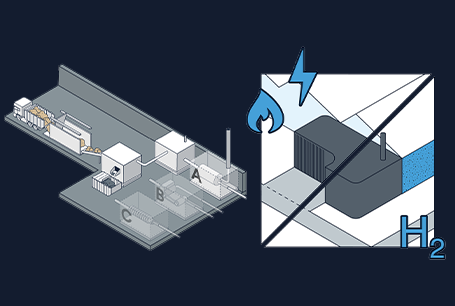

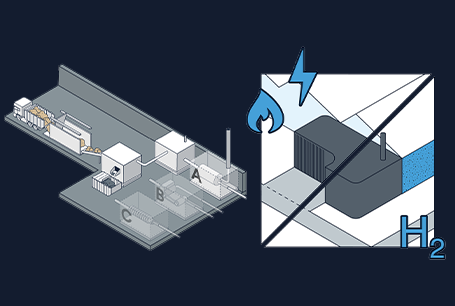

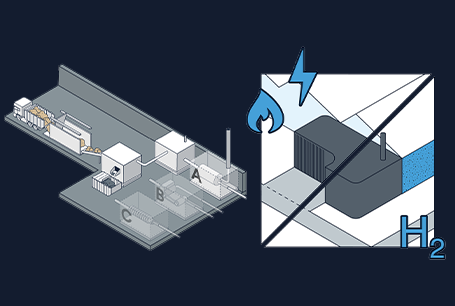

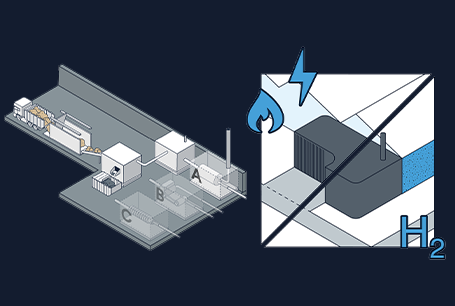

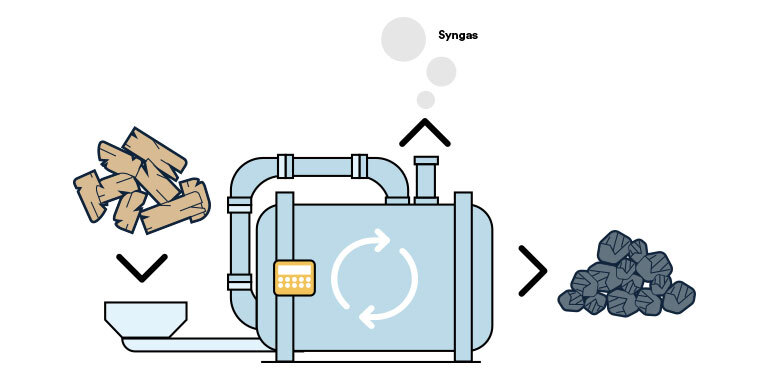

The modules produce renewable energy from biomass using pyrolysis.

When heated in a low-oxygen atmosphere to around 500°C, the biomass produces a solid residue, biochar, and a synthesis gas.

The resulting solid part, biochar, sequesters carbon from the biomass for several hundred years.

This plant-based charcoal is therefore a powerful carbon sink, and as such is listed as a "Negative Emission Technology"

by the IPCC.

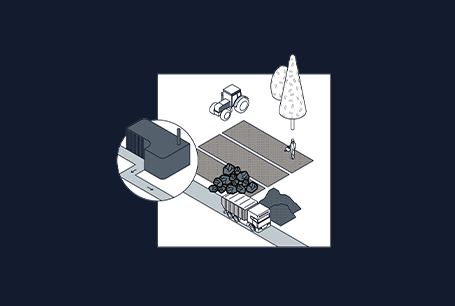

Biochar can be put to many uses : building material, water filtration, soil enrichment.

It improves the potential of natural fertilisers and therefore crop yields,

while reducing fertiliser inputs.

The carbon sequestration in the biochar is certified by very high-quality carbon credits.

Carbonloop ensures this certification with international labels and transfers these carbon credits to the company,

which can then integrate them into its carbon accounting. This enables the company to offset

its carbon emissions directly on site and not on the other side of the world.

The Carbonloop production unit is supplied locally with biomass residues that would not

otherwise be used (natural or industrial residues from forest maintenance, agriculture

or the wood industry, such as bark, wood chips or straw).

The production unit consists of 3 modules, each the size of a 40-foot container,

which arrive already assembled. It is easy to install on an industrial site.

The modules produce renewable energy from biomass using pyrolysis.

When heated in a low-oxygen atmosphere to around 500°C, the biomass produces a solid residue, biochar, and a synthesis gas.

The resulting solid part, biochar, sequesters carbon from the biomass for several hundred years.

This plant-based charcoal is therefore a powerful carbon sink, and as such is listed as a "Negative Emission Technology"

by the IPCC.

Biochar can be put to many uses : building material, water filtration, soil enrichment.

It improves the potential of natural fertilisers and therefore crop yields,

while reducing fertiliser inputs.

The carbon sequestration in the biochar is certified by very high-quality carbon credits.

Carbonloop ensures this certification with international labels and transfers these carbon credits to the company,

which can then integrate them into its carbon accounting. This enables the company to offset

its carbon emissions directly on site and not on the other side of the world.

The Carbonloop production unit is supplied locally with biomass residues that would not

otherwise be used (natural or industrial residues from forest maintenance, agriculture

or the wood industry, such as bark, wood chips or straw).

The production unit consists of 3 modules, each the size of a 40-foot container,

which arrive already assembled. It is easy to install on an industrial site.

The modules produce renewable energy from biomass using pyrolysis.

When heated in a low-oxygen atmosphere to around 500°C, the biomass produces a solid residue, biochar, and a synthesis gas.

The resulting solid part, biochar, sequesters carbon from the biomass for several hundred years.

This plant-based charcoal is therefore a powerful carbon sink, and as such is listed as a "Negative Emission Technology"

by the IPCC.

Biochar can be put to many uses : building material, water filtration, soil enrichment.

It improves the potential of natural fertilisers and therefore crop yields,

while reducing fertiliser inputs.

The carbon sequestration in the biochar is certified by very high-quality carbon credits.

Carbonloop ensures this certification with international labels and transfers these carbon credits to the company,

which can then integrate them into its carbon accounting. This enables the company to offset

its carbon emissions directly on site and not on the other side of the world.

The Carbonloop production unit is supplied locally with biomass residues that would not

otherwise be used (natural or industrial residues from forest maintenance, agriculture

or the wood industry, such as bark, wood chips or straw).

The production unit consists of 3 modules, each the size of a 40-foot container,

which arrive already assembled. It is easy to install on an industrial site.

The modules produce renewable energy from biomass using pyrolysis.

When heated in a low-oxygen atmosphere to around 500°C, the biomass produces a solid residue, biochar, and a synthesis gas.

The resulting solid part, biochar, sequesters carbon from the biomass for several hundred years.

This plant-based charcoal is therefore a powerful carbon sink, and as such is listed as a "Negative Emission Technology"

by the IPCC.

Biochar can be put to many uses : building material, water filtration, soil enrichment.

It improves the potential of natural fertilisers and therefore crop yields,

while reducing fertiliser inputs.

The carbon sequestration in the biochar is certified by very high-quality carbon credits.

Carbonloop ensures this certification with international labels and transfers these carbon credits to the company,

which can then integrate them into its carbon accounting. This enables the company to offset

its carbon emissions directly on site and not on the other side of the world.

The Carbonloop production unit is supplied locally with biomass residues that would not

otherwise be used (natural or industrial residues from forest maintenance, agriculture

or the wood industry, such as bark, wood chips or straw).

The production unit consists of 3 modules, each the size of a 40-foot container,

which arrive already assembled. It is easy to install on an industrial site.

The modules produce renewable energy from biomass using pyrolysis.

When heated in a low-oxygen atmosphere to around 500°C, the biomass produces a solid residue, biochar, and a synthesis gas.

The resulting solid part, biochar, sequesters carbon from the biomass for several hundred years.

This plant-based charcoal is therefore a powerful carbon sink, and as such is listed as a "Negative Emission Technology"

by the IPCC.

Biochar can be put to many uses : building material, water filtration, soil enrichment.

It improves the potential of natural fertilisers and therefore crop yields,

while reducing fertiliser inputs.

The carbon sequestration in the biochar is certified by very high-quality carbon credits.

Carbonloop ensures this certification with international labels and transfers these carbon credits to the company,

which can then integrate them into its carbon accounting. This enables the company to offset

its carbon emissions directly on site and not on the other side of the world.

The Carbonloop production unit is supplied locally with biomass residues that would not

otherwise be used (natural or industrial residues from forest maintenance, agriculture

or the wood industry, such as bark, wood chips or straw).

The production unit consists of 3 modules, each the size of a 40-foot container,

which arrive already assembled. It is easy to install on an industrial site.

The modules produce renewable energy from biomass using pyrolysis.

When heated in a low-oxygen atmosphere to around 500°C, the biomass produces a solid residue, biochar, and a synthesis gas.

The resulting solid part, biochar, sequesters carbon from the biomass for several hundred years.

This plant-based charcoal is therefore a powerful carbon sink, and as such is listed as a "Negative Emission Technology"

by the IPCC.

Biochar can be put to many uses : building material, water filtration, soil enrichment.

It improves the potential of natural fertilisers and therefore crop yields,

while reducing fertiliser inputs.

The carbon sequestration in the biochar is certified by very high-quality carbon credits.

Carbonloop ensures this certification with international labels and transfers these carbon credits to the company,

which can then integrate them into its carbon accounting. This enables the company to offset

its carbon emissions directly on site and not on the other side of the world.

The Carbonloop production unit is supplied locally with biomass residues that would not

otherwise be used (natural or industrial residues from forest maintenance, agriculture

or the wood industry, such as bark, wood chips or straw).

The production unit consists of 3 modules, each the size of a 40-foot container,

which arrive already assembled. It is easy to install on an industrial site.

The modules produce renewable energy from biomass using pyrolysis.

When heated in a low-oxygen atmosphere to around 500°C, the biomass produces a solid residue, biochar, and a synthesis gas.

The resulting solid part, biochar, sequesters carbon from the biomass for several hundred years.

This plant-based charcoal is therefore a powerful carbon sink, and as such is listed as a "Negative Emission Technology"

by the IPCC.

Biochar can be put to many uses : building material, water filtration, soil enrichment.

It improves the potential of natural fertilisers and therefore crop yields,

while reducing fertiliser inputs.

The carbon sequestration in the biochar is certified by very high-quality carbon credits.

Carbonloop ensures this certification with international labels and transfers these carbon credits to the company,

which can then integrate them into its carbon accounting. This enables the company to offset

its carbon emissions directly on site and not on the other side of the world.

The Carbonloop production unit is supplied locally with biomass residues that would not

otherwise be used (natural or industrial residues from forest maintenance, agriculture

or the wood industry, such as bark, wood chips or straw).

The production unit consists of 3 modules, each the size of a 40-foot container,

which arrive already assembled. It is easy to install on an industrial site.

The modules produce renewable energy from biomass using pyrolysis.

When heated in a low-oxygen atmosphere to around 500°C, the biomass produces a solid residue, biochar, and a synthesis gas.

The resulting solid part, biochar, sequesters carbon from the biomass for several hundred years.

This plant-based charcoal is therefore a powerful carbon sink, and as such is listed as a "Negative Emission Technology"

by the IPCC.

Biochar can be put to many uses : building material, water filtration, soil enrichment.

It improves the potential of natural fertilisers and therefore crop yields,

while reducing fertiliser inputs.

The carbon sequestration in the biochar is certified by very high-quality carbon credits.

Carbonloop ensures this certification with international labels and transfers these carbon credits to the company,

which can then integrate them into its carbon accounting. This enables the company to offset

its carbon emissions directly on site and not on the other side of the world.

The Carbonloop production unit is supplied locally with biomass residues that would not

otherwise be used (natural or industrial residues from forest maintenance, agriculture

or the wood industry, such as bark, wood chips or straw).

The production unit consists of 3 modules, each the size of a 40-foot container,

which arrive already assembled. It is easy to install on an industrial site.

The modules produce renewable energy from biomass using pyrolysis.

When heated in a low-oxygen atmosphere to around 500°C, the biomass produces a solid residue, biochar, and a synthesis gas.

The resulting solid part, biochar, sequesters carbon from the biomass for several hundred years.

This plant-based charcoal is therefore a powerful carbon sink, and as such is listed as a "Negative Emission Technology"

by the IPCC.

Biochar can be put to many uses : building material, water filtration, soil enrichment.

It improves the potential of natural fertilisers and therefore crop yields,

while reducing fertiliser inputs.

The carbon sequestration in the biochar is certified by very high-quality carbon credits.

Carbonloop ensures this certification with international labels and transfers these carbon credits to the company,

which can then integrate them into its carbon accounting. This enables the company to offset

its carbon emissions directly on site and not on the other side of the world.

The Carbonloop production unit is supplied locally with biomass residues that would not

otherwise be used (natural or industrial residues from forest maintenance, agriculture

or the wood industry, such as bark, wood chips or straw).

The production unit consists of 3 modules, each the size of a 40-foot container,

which arrive already assembled. It is easy to install on an industrial site.

The modules produce renewable energy from biomass using pyrolysis.

When heated in a low-oxygen atmosphere to around 500°C, the biomass produces a solid residue, biochar, and a synthesis gas.

The resulting solid part, biochar, sequesters carbon from the biomass for several hundred years.

This plant-based charcoal is therefore a powerful carbon sink, and as such is listed as a "Negative Emission Technology"

by the IPCC.

Biochar can be put to many uses : building material, water filtration, soil enrichment.

It improves the potential of natural fertilisers and therefore crop yields,

while reducing fertiliser inputs.

The carbon sequestration in the biochar is certified by very high-quality carbon credits.

Carbonloop ensures this certification with international labels and transfers these carbon credits to the company,

which can then integrate them into its carbon accounting. This enables the company to offset

its carbon emissions directly on site and not on the other side of the world.

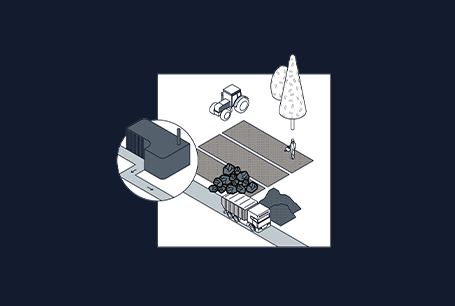

Biomass is all organic matter of animal or vegetable origin.

Part of this biomass (food or agricultural waste, wood, leaves, slurry…) can be recovered in the form of energy (gas, electricity, heat). Carbonloop only uses untreated biomass waste, primarily forest management “offcuts”.

Pyrolysis consists of heating biomass waste to a temperature ranging from 350°C to 650°C in the absence of oxygen, without combustion.

This process has two main advantages:

BIOCHAR IS A PLANT-BASED CHARCOAL-LIKE SUBSTANCE OBTAINED THROUGH BIOMASS PYROLYSIS

It is predominantly made up of carbon and can be put to many uses (building material, water filtration, soil enrichment…). In terms of agronomic uses, it improves fertility and increases crop yields, making it possible to reduce fertiliser inputs.

AN ULTRA EFFECTIVE CARBON SINK

When used as a soil improver, one tonne of biochar can sustainably sequester about 2.6 tonnes of CO2.

Compared with other carbon sinks, biochar presents 3 major advantages:

IMMEDIACY OF SEQUESTRATION

Sequestration takes place at the same time as energy production.

DURATION OF SEQUESTRATION

The carbon contained in the biochar remains stable for several hundred years.

LOCALISATION OF THE IMPACT

Carbon offsetting is done on-site in direct relation to your activities, not on the other side of the planet.

A carbon credit is a document certifying that a tonne of CO2 has been avoided or sequestered (taken from the atmosphere) through a project. For a good quality carbon credit, the generating project must meet the following criteria as a minimum:

ADDITIONALITY: the project would not have happened without the creation and sale of carbon credits.

MEASURABILITY: the quantity of CO2 that has been avoided or sequestered is quantifiable or verifiable.

DURABILITY: the project must be long term and the CO2 sequestration irreversible.

LOCALITÉ: the project must be located as close as possible to the CO2 emissions.